I.Summary

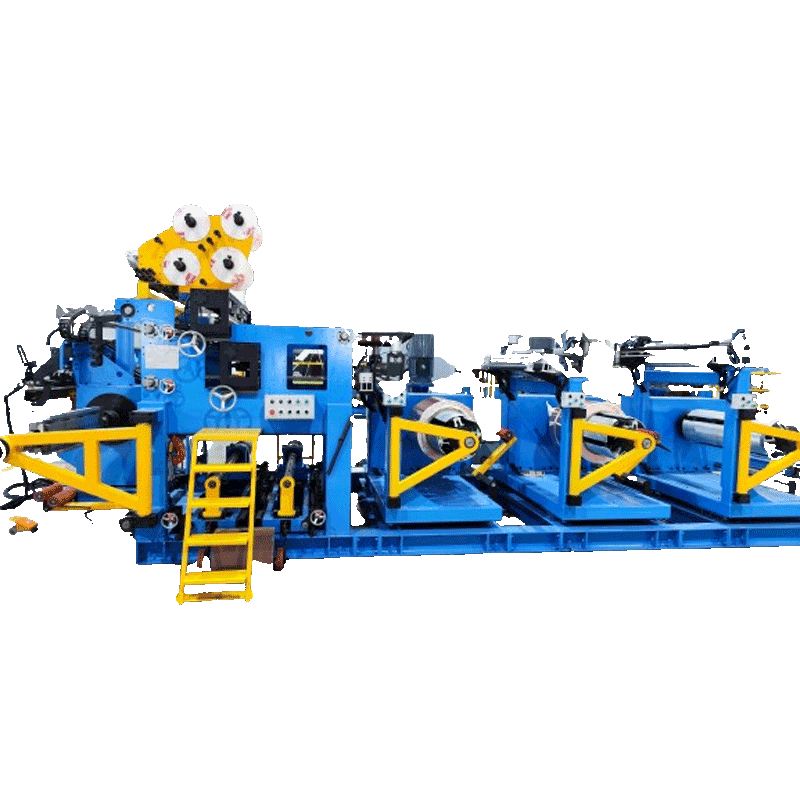

LV foil coil inoshandisa kukora kwakasiyana mhangura kana aluminium foil sekondakita, yakafara bhendi yemhando yekudzivirira zvinhu seyakapetwa kaviri, kupeta kwakazara mufoil mhando yekumonera muchina, kugadzira roll coil.

Iyi midziyo inogona zvakare kuiswa kune yakafanana coil winding yemagetsi indasitiri.

Muchina uyu unotora PLC yekudzora nzira ine hunhu hwepamusoro dhigirii re automation.

Ⅱ.Kuumbwa uye Basa reEquipment

BR/III-1100 Three-Layer Foil Winding Machine inosanganisira

1) Foil de-coiling mudziyo 2) Winding mudziyo 3) Layer insulation decoiling mudziyo

4) Iyo huru furemu zvikamu 5) Welding mudziyo 6) Deburring uye kuchenesa mudziyo

7) Kucheka mudziyo 8) Iyo yekupedzisira insulation uncoiling mudziyo nezvimwe

III. Main Technical Parameters

| Sr# | ITEM | KUTAURA |

| 1 | Coil | Processing range |

| 1.1 | Axial urefu | 250 ~1100 mm |

| 1.2 | Axial urefu (Batanidza lead) | 400~1760 mm (ine lead RH 16 inch, LH 10inch) |

| 1.3 | Kunze dhayamita (Max) | Φ1000 |

| 1.4 | Coil fomu | Round/cylindrical/rectangular/coil uremu ≤2000KG |

| 1.5 | Center urefu | 850mm |

| 2 | Coil Material | Copper foil, aluminium foil |

| 2.1 | Upamhi | 250—1100 mm |

| 2.2 | Hukobvu (Max) (Total ukobvu) | Mhangura foil: 0.3-2.5mm Aluminium foil: 0.4 ~ 3mm |

| 2.3 | Coil mukati dhayamita | Φ400-500mm |

| 2.4 | Coil yekunze dhayamita (Max) | φ1000mm |

| De-coiler | Yakazvimirira matatu seti |

| 3.1 | Hurefu hwekubereka humburumbira | 1150 mm |

| 3.2 | Kuwedzera huwandu hwekubereka humburumbira | Φ380~φ520 |

| 3.3 | Kutakura simba (Max) | 2000KG |

| 3.4 | Simba rekuwedzera (Electric) | 0~15000N Kuwedzera simba risingachinjike |

| 3.5 | Mode of offset kugadzirisa | Manual/Otomatiki |

| Winding machine |

|

| 4.1 | Winding speed | 0~20 rpm |

| 4.2 | Kushanda torque (Max) | ≥ 8000N·M |

| 4.3 | Kupeta simba | 20-30 KW |

| 4.4 | Speed control nzira | Frequency kutendeuka stepless speed regulation |

| 4.5 | Winding shaft | 50*90mm |

| 5 | Welding mudziyo |

|

| 5.1 | Welding mode | TIG |

| 5.2 | Kuitisa bar welding ukobvu | ≤ 20mm |

| 5.3 | Welding speed | Auto-kumhanya kudzora 0~1m / min Nhanho isina nhanho yekumhanyisa mutemo |

| 6 | Kucheka mudziyo |

|

| 6.1 | Kucheka fomu | Lead Screw Cutting Disc |

| 6.2 | Cutting speed | 1.5 m / min |

| 6.3 | Kucheka kureba | 1150mm |

| 7. | Layer insulatinguncoilmudziyo | |

| 7.1 | Layer insulation yakaiswa shaft | 2 seti |

| 7.2 | Layer insulation roll yekunze dhayamita | ≤φ400 mm |

| 7.3 | Layer insulation roll yemukati dhayamita | φ76 mm |

| 7.4 | Layer insulation roll width | 250 ~1150 mm |

| 7.5 | De-coil shaft tension nzira | Pneumatic type |

| 8. | Theendinsulation uncoiling mudziyo |

|

| 8.1 | Quantity | Kuruboshwe uye kurudyi imwe neimwe 4 seti |

| 8.2 | Iyo yekupedzisira insulation kunze dhayamita | ≤φ350 mm |

| 8.3 | Iyo yekupedzisira insulation inner dhayamita | Φ56 mm |

| 8.4 | Iyo yekupedzisira insulation upamhi | 10-100mm |

| 9. | Rectifying mudziyo (foil alignment) | Iyakazvimirira 3 seti |

| 9.1 | Kugadzirisa maitiro | Photoelectric system |

| 9.2 | Kugadzirisa chokwadi | Random±0 .4 mm 20 akaturikidzana coil ±1mm |

| 10. | Electric control system | PLC otomatiki kudzora maitiro |

| 10.1 | Nhamba yedhijitari | 4-digital (0–9999.9))Kuverenga chokwadi 0.1 kutendeuka |

| 10.2 | Operation interface | Color touch screen |

| 11. | Zvimwe |

|

| 11.1 | Layer insulation yekucheka mudziyo | Configuration seti mbiri |

| 11.2 | Foil zvinhu mipendero deburring mudziyo | Configuration matatu seti |

| 11.3 | Foil zvinhu zvekuchenesa mudziyo | Configuration matatu seti |

| 11.4 | Welding mvura inotonhorera tangi | configuration |

| 11.5 | Magetsi | 3-PH,380V/50HZ (Inogona kugadzirwa) |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com